Calibrating tools like levels and torque wrenches is essential to guarantee your measurements are accurate, safe, and reliable. Proper calibration aligns your tools with standard references, correcting any drift or inaccuracies from regular use. This process involves comparing tools against known benchmarks and adjusting them if needed, often with specialized equipment. Continuously maintaining calibration helps prevent costly mistakes and safety issues. Keep going to discover detailed steps on how to perform these calibrations yourself and keep your tools in top shape.

Key Takeaways

- Calibration ensures measurement accuracy, critical for safety and quality in construction and engineering projects.

- Regular calibration aligns tools with standards, detecting and correcting drift or inaccuracies over time.

- Testing methods compare tool readings against calibrated references to verify proper function.

- Proper calibration procedures involve adjustments per manufacturer guidelines or specialized calibration equipment.

- Maintaining calibration records and scheduling regular checks sustain tool reliability and regulatory compliance.

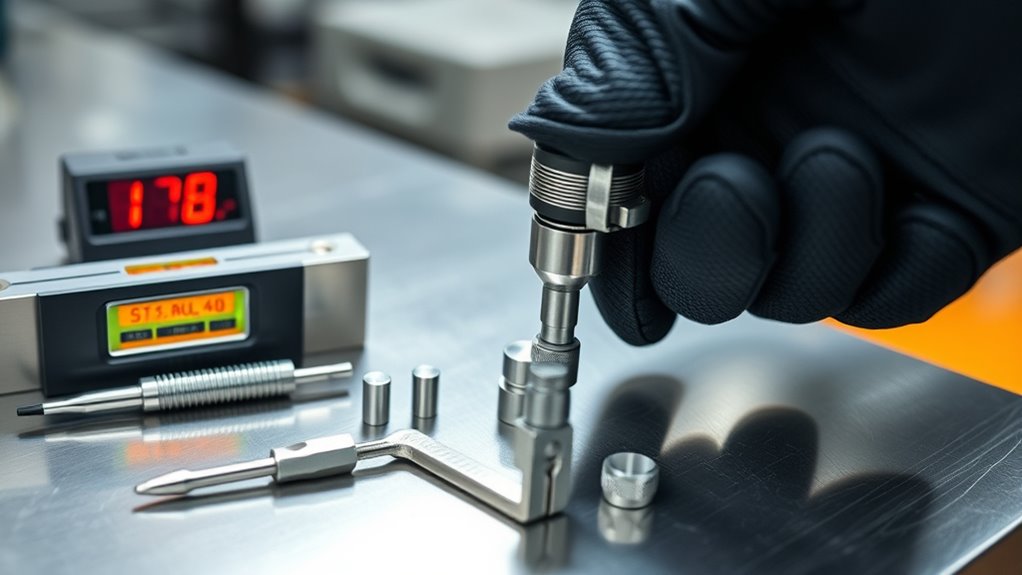

Have you ever wondered why precise measurements matter in your work? When you’re working with tools like levels, torque wrenches, or other precision instruments, the accuracy of each measurement directly impacts the quality and safety of your projects. That’s where proper tool calibration becomes essential. Calibration procedures are designed to ensure your tools provide reliable readings, which is critical whether you’re constructing buildings, assembling machinery, or performing maintenance tasks. Without calibration, even minor inaccuracies can lead to significant issues, such as structural failures or improper torque application.

Performing regular tool accuracy testing is the first step toward maintaining reliable measurements. Testing involves comparing your tool’s readings against a standard or known reference. For example, with a level, you’d check its accuracy by placing it on a calibrated surface and verifying that bubbles are centered. For torque wrenches, you might use a calibration device to measure the torque output at different settings. These tests reveal whether your tools are still within acceptable tolerances or if they’ve drifted out of calibration. If you find discrepancies, it’s essential to follow proper calibration procedures to bring the tools back into proper working condition.

Regular accuracy testing ensures your tools remain reliable and within calibration tolerances.

Calibration procedures are straightforward but require attention to detail. Typically, they involve adjusting the tool according to manufacturer specifications or standardized guidelines. For levels, calibration may mean re-aligning the vial or replacing damaged components. For torque wrenches, calibration often involves using a calibration device or machine that applies precise torque values, allowing you to identify and correct inaccuracies. These procedures often require specialized equipment or professional calibration services, especially for highly precise tools. Regular calibration helps catch any drift in tool accuracy early, preventing errors in your work and ensuring consistent results. Additionally, understanding the thermal behavior of your tools can help you maintain their accuracy in different working environments.

Keeping your tools calibrated isn’t just a one-time task; it’s an ongoing process. Establish a calibration schedule based on how frequently you use your tools and the environments in which they operate. Heavy use or exposure to harsh conditions can accelerate calibration drift, so frequent testing and recalibration are necessary. Maintaining proper calibration records is also essential—not only for quality assurance but also for compliance with industry standards and safety regulations. When you trust your tools to deliver accurate measurements, you reduce the risk of costly mistakes and improve overall project quality.

Frequently Asked Questions

How Often Should I Calibrate My Tools?

You should calibrate your tools regularly based on their calibration frequency recommendations and how often you use them. Typically, calibrate torque wrenches and levels at least once a year or after significant impacts or repairs. Remember, proper calibration helps extend your tools’ lifespan and ensures accuracy. Keep track of calibration dates to maintain peak performance and prevent costly mistakes in your work.

What Are the Signs of a Miscalibrated Tool?

You’ll notice a miscalibrated tool when its accuracy starts to slip, such as inconsistent readings or measurements. Calibration indicators, like difficulty in achieving precise torque or levels, also signal issues. If your tools give fluctuating results or don’t meet specified standards, it’s time to calibrate. Regular checks help guarantee your tools maintain proper calibration, preventing errors and ensuring reliable, accurate work every time.

Can I Calibrate Tools at Home or Need Professionals?

You can try DIY calibration if you’re comfortable with precision, but it’s often best to trust professional services for accuracy. Think of it like tuning a musical instrument—you might get close, but a professional ensures perfect pitch. For critical tools, professional calibration guarantees reliability and safety. If you’re unsure, consulting experts helps avoid costly mistakes, ensuring your tools perform flawlessly when you need them most.

What Calibration Standards Should I Follow?

You should follow industry standards like ANSI, ISO, or ASME to guarantee measurement accuracy. Check calibration intervals recommended by manufacturers or industry guidelines to maintain precision. Use certified calibration references or standards to verify your tools regularly. This approach helps you keep your tools accurate, reliable, and compliant with safety regulations, whether you’re calibrating at home or professionally. Always document calibration results for future reference.

How Does Temperature Affect Tool Calibration Accuracy?

Temperature affects your tool calibration accuracy through thermal expansion and temperature drift. When temperatures fluctuate, materials in your tools expand or contract, causing measurement deviations. This thermal expansion can lead to inaccurate readings if not compensated for. Temperature drift over time can also cause calibration to shift. To maintain accuracy, calibrate your tools in stable environments and regularly check for temperature-related discrepancies, ensuring reliable measurements every time.

Conclusion

Regularly calibrating your tools is like tending a well-loved garden—you keep things in harmony, preventing small issues from blossoming into bigger problems. By giving your levels and torque wrenches a gentle tune-up, you ensure every project remains precise and reliable. A little attention now can save you from unwelcome surprises later. So, think of calibration as a quiet investment in your craftsmanship—one that pays off with consistent, trustworthy results every time you pick up your tools.